#Cashew processing process

Cashew processing process

Cashew processing process

1. What is shelled cashews?

Shelling cashews is the process of removing the hard shell and thin skin surrounding the cashew nut to obtain the kernel inside, ready for consumption. This is an important step in cashew processing, requiring careful handling to ensure the quality of the nuts. Here are the detailed steps of the cashew shelling process:

Harvesting and Drying

- Harvesting: Cashews are harvested from the tree when the cashew apples are fully ripe.

- Drying: After harvesting, cashews are dried under the sun or in drying ovens to reduce moisture and harden the shell.

Steaming Cashews

- Steaming: Cashews are steamed in hot water or steam to soften the hard shell. This process also helps reduce the adhesion of the shell oil.

Shell Removal

- Shelling Machine: Use a cashew shelling machine to remove the hard outer shell. The machine can be adjusted to ensure the cashew nut inside is not damaged.

- Manual Shelling: In some places, workers may manually shell cashews using knives or special tools. This process requires skill and care.

.jpg)

Removing the Thin Skin

- Roasting: After removing the hard shell, cashews are lightly roasted to soften and easily remove the thin skin surrounding the nut.

- Rubbing: Use a rubbing machine or hands to remove the thin skin. This process makes the cashews clean and ready for use.

Sorting and Packaging

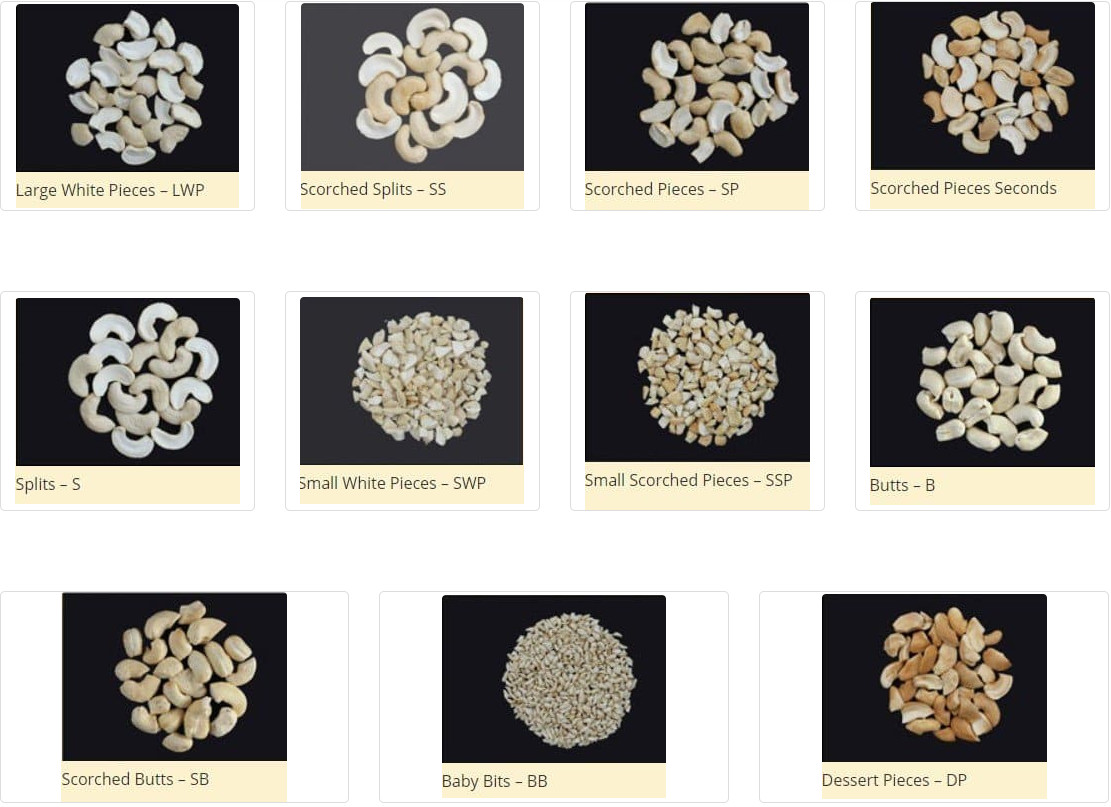

- Sorting: Cashews are sorted by size, color, and quality after shelling. Broken or substandard cashews are removed.

- Packaging: Sorted cashews are sealed in packages for storage and transport. The packaging process helps protect the cashews from moisture, light, and environmental impacts.

Quality Control

- Inspection: Before reaching the market, cashews undergo thorough quality inspection to ensure they meet standards for taste, crispness, and nutrition.

Notes When Shelling Cashews

- Using Safe Tools: Use safe tools and machines to avoid injuries when shelling.

- Maintaining Hygiene: Ensure the shelling and processing steps are conducted under good sanitary conditions to ensure food safety.

The cashew shelling process requires careful and meticulous handling to ensure the nuts are not broken and maintain their best quality. By following these steps correctly, you can enjoy delicious and nutritious cashews.

2. Technical requirements

Shelling cashew nuts requires precise technique and safety measures to ensure the quality of the nuts inside is not compromised. Here are the detailed technical requirements for shelling cashew nuts:

Preparation Before Shelling

Selecting Cashew Nuts:

- Sorting: Choose cashew nuts of uniform size and shape to ensure a smooth and efficient shelling process.

- Quality Check: Remove any nuts that are cracked, broken, or show signs of damage before proceeding with shelling.

Hard Shell Removal Process

Steaming Cashew Nuts:

- Hot Water or Steam: Steam cashew nuts in hot water or steam to soften the hard shell, making the shelling process easier.

Using a Shelling Machine:

- Machine Adjustment: Adjust the shelling machine to fit the size of the cashew nuts, ensuring the shell is removed without damaging the nuts inside.

- Pressure Control: Control the pressure of the shelling machine to avoid breaking or deforming the cashew nuts.

Manual Shelling:

- Special Tools: Use knives or special tools to carefully remove the hard shell.

- Careful Technique: Perform the shelling process carefully to avoid damaging the cashew nuts.

Removing the Thin Skin

Light Roasting Cashew Nuts:

- Proper Temperature: Lightly roast the cashew nuts at a moderate temperature to soften the thin skin without burning or discoloring the nuts.

- Appropriate Time: Control the roasting time to achieve the best results in removing the thin skin.

Using a Rubbing Machine:

- Gentle Rubbing: Use a rubbing machine to gently remove the thin skin without damaging the nuts.

- Result Check: Inspect the nuts after rubbing to ensure all the thin skin has been completely removed.

Sorting and Packaging

- Size and Quality: Sort the cashew nuts by size, color, and quality. Remove any broken or substandard nuts.

- Sealed Packaging: Pack the cashew nuts in sealed packages for storage and transportation, ensuring the quality is maintained.

Safety and Hygiene

Using Safe Tools:

- Protective Gear: Ensure workers use adequate protective gear such as gloves, masks, and safety goggles when shelling cashew nuts.

- Tool Hygiene: Ensure tools and machines are cleaned thoroughly before and after use.

Ensuring Food Safety:

- Sanitation Procedures: Adhere to strict sanitation procedures during the shelling and processing of cashew nuts to ensure food safety.

- Quality Inspection: Inspect the quality of cashew nuts after shelling to ensure they are free from contamination or damage.

Notes When Shelling Cashew Nuts

Choosing the Right Time: Shell cashew nuts in dry weather conditions to avoid moisture and mold.

Ensuring Environmental Conditions: Ensure the working environment has appropriate temperature and humidity to maintain the quality of the cashew nuts.

Shelling cashew nuts requires technique and care to ensure the nuts are not broken and maintain the best quality. Properly following the technical requirements will help optimize the production process and ensure quality products for consumers.

3. Manual peeling method

Hand-shelling cashews is a traditional method that requires precision and care to ensure the quality of the nuts inside. Here are the detailed steps of the manual cashew shelling process:

Harvesting and Drying

- Harvesting: Collect cashew nuts from the tree when the cashew apples are fully ripe.

.jpg)

- Drying: After harvesting, dry the cashews under the sun or in drying ovens to reduce moisture and harden the shell.

Steaming Cashews

- Steaming: Steam the cashews in hot water or steam to soften the hard shell. This makes the shelling process easier and helps reduce the adhesion of the shell oil.

Shell Removal

- Special Tools: Use knives or special tools to carefully remove the hard outer shell.

- Careful Technique: Perform the shelling process with precision to avoid damaging the nuts inside. Insert the knife into the seam of the shell and gently twist to open it.

Removing the Thin Skin

- Light Roasting: After removing the hard shell, lightly roast the cashews at a moderate temperature to soften the thin skin without burning or discoloring the nuts.

- Rubbing: Use a rubbing tool or your hands to gently remove the thin skin. This process ensures the cashews are clean and ready for use.

Sorting and Packaging

- Sorting: Sort the cashews by size, color, and quality after shelling. Remove any broken or substandard nuts.

- Sealed Packaging: Pack the sorted cashews in sealed packages to maintain their quality during storage and transportation. This helps protect the nuts from moisture, light, and environmental impacts.

Safety and Hygiene

- Using Safe Tools: Ensure workers use adequate protective gear such as gloves, masks, and safety goggles when shelling cashews.

- Tool Hygiene: Clean the tools thoroughly before and after use to maintain hygiene and ensure food safety.

Quality Control

- Inspection: Inspect the quality of the cashew nuts after shelling to ensure they meet standards for taste, crispness, and nutrition.

Notes When Hand-Shelling Cashews

- Choosing the Right Time: Shell cashew nuts in dry weather conditions to avoid moisture and mold.

- Ensuring Environmental Conditions: Maintain appropriate temperature and humidity in the working environment to preserve the quality of the cashews.

Hand-shelling cashews requires skill and attention to detail to ensure the nuts are not broken and maintain their best quality. By following these steps correctly, you can enjoy delicious and nutritious cashews.

4. Machine peeling method

Shelling cashews using machines is a modern method that increases efficiency and reduces labor compared to manual methods. Here are the detailed steps of the machine shelling process:

Harvesting and Drying

- Harvesting: Cashew nuts are collected from the tree when the cashew apples are fully ripe.

- Drying: After harvesting, the cashews are dried under the sun or in drying ovens to reduce moisture and harden the shell.

Steaming Cashews

- Steaming: The cashews are steamed in hot water or steam to soften the hard shell. This step makes the shelling process easier and helps reduce the adhesion of the shell oil.

Machine Shelling

- Shelling Machine: A cashew shelling machine is used to crack and remove the hard outer shell. The machine can be adjusted to fit the size of the cashew nuts, ensuring efficient shelling without damaging the nuts inside.

- Feeding Mechanism: Cashew nuts are fed into the machine, usually via a conveyor belt or hopper.

- Cracking Mechanism: The machine uses a combination of rollers, blades, and pressure to crack the hard shell without affecting the kernel.

- Separation Mechanism: The cracked shells and kernels are separated automatically by the machine, with kernels being collected in a different compartment.

Removing the Thin Skin

- Light Roasting: After shelling, the cashews are lightly roasted at a moderate temperature to loosen the thin skin surrounding the nuts.

- Rubbing Machine: A rubbing machine is used to gently remove the thin skin from the cashews. This ensures the nuts are clean and ready for further processing or consumption.

Sorting and Packaging

- Sorting: After shelling, the cashews are sorted by size, color, and quality. Machines equipped with optical sensors can detect and remove broken or substandard nuts.

- Sealed Packaging: The sorted cashews are then packed in sealed packages to maintain their quality during storage and transportation. This process helps protect the nuts from moisture, light, and environmental impacts.

Quality Control

- Inspection: Before reaching the market, cashews undergo thorough quality inspection to ensure they meet standards for taste, crispness, and nutrition. Machines can also perform automated quality checks to maintain consistency.

Safety and Hygiene

- Using Safe Equipment: Ensure workers use adequate protective gear such as gloves, masks, and safety goggles when operating shelling machines.

- Equipment Hygiene: Regularly clean and maintain the machines to ensure hygiene and optimal performance. This includes sanitizing parts that come into contact with the cashews.

Efficiency and Cost

- Efficiency: Machine shelling significantly increases the efficiency of the shelling process, allowing large volumes of cashews to be processed quickly.

- Cost: While the initial investment in shelling machines can be high, the reduction in labor costs and increased productivity often offset the expenditure over time.

Notes When Machine-Shelling Cashews

- Proper Adjustment: Ensure the shelling machine is properly adjusted to avoid breaking or damaging the nuts.

- Regular Maintenance: Schedule regular maintenance and inspections of the machines to prevent malfunctions and ensure consistent quality.

Using machines to shell cashews improves productivity and ensures high-quality nuts while reducing labor efforts. By following these steps and maintaining proper machine adjustments and hygiene, you can optimize the cashew shelling process.

Xem thêm: Bóc vỏ hạt điều là gì? Phương pháp bóc vỏ thủ công & bóc vỏ bằng máy

Learn more: What is Cashew Shelling? Manual Shelling & Machine Shelling Methods

Brian Dương

Brian Dương

TVQuản trị viênQuản trị viên

Xin chào quý khách. Quý khách hãy để lại bình luận, chúng tôi sẽ phản hồi sớm